Varosa Engg. Lab Provides Electronic Modules Repairing Services for Rolls-Royce, Kongsberg Marine Controller PCB Cards

At Varosa Engg R&D Laboratory we have the experience of repairing Rolls-Royce, Kongsberg Marine Controller PCB modules and expertise to make defective control cards functional at cost effective manner.

We do FREE inspections of Rolls-Royce, Kongsberg etc. Controller Cards in our R&D Lab and we provide economical solutions to customer for Repairing Cost.

We provide an OEM level of quality service at a competitive, non-OEM price. We have the ability to repair and calibrate many Rolls-Royce & Kongsberg units from many different Manufacturers. With our state-of-the-Art technologies and dedicated technicians, our staffs are able to ease the pain of any repair service order.

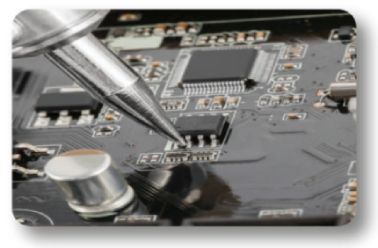

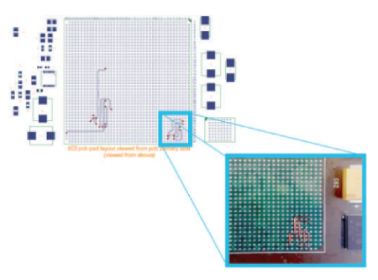

We have unique way of repairing the products through Reverse Engineering Method (Tracing each and every track on the PCB and developing a circuit diagram based on that) which helps us understand the problem to the root level and rectify it.

We have a massive inventory of Electronic Components at our workshop.

We provide free quotation for all the items sent to us at our works. All the items that we receive are evaluated first before determining the repairing price. Quality Service targets are set in our mind right from the arrival of the instruments at our workshop and till the time it is installed back at your premises.

We believe in strong warranty policy and effective quality assurance.

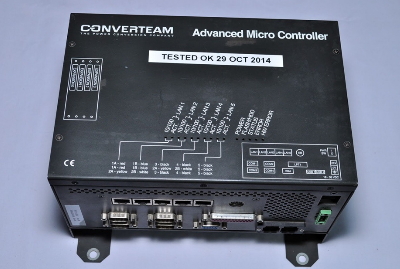

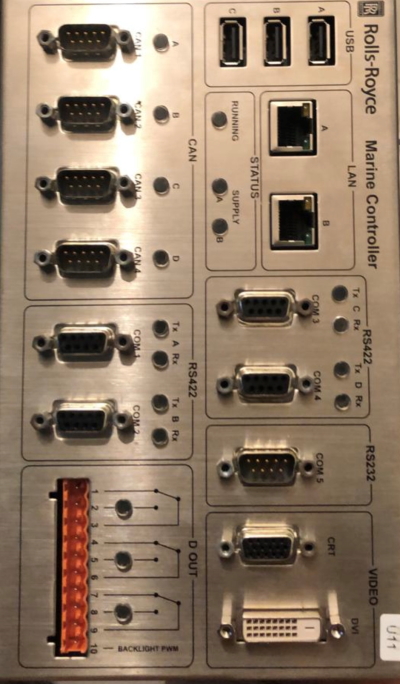

Serviced Controller Cards Stocks available for Sales:

- ROLLS-ROYCE MARINE CONTROLLER H1127 0101-000068308

- ROLLS-ROYCE

- MARINE CONTROLLERTYPE: H1127.0101

- RR PART: 000068308

- H6045/433 MHZ

- ROLLS-ROYCE

- MARINE CONTROLLER

- Rolls Royce - Card Marine Controllers - H1111.0103

Varosa Engg offers a suite of PCB repair & rework services that is fully controlled and ESD compliant. Our facilities are ISO 9001:2008 accredited and we use the latest software controlled circuit board repair stations and work to recognised IPC and JEDEC workmanship standards to ensure accurate profile settings for the most complex reworks.

- Pad & Track Repair / Laminate Repair

- Rework / Engineering Change Notices

- Component Level Debug

- Inspection / Verification

- PCB Debug

- Changing a PTH device using an individual desoldering tool or miniwave.

- An alternative to costly investment in rework equipment and a ‘turn on turn off’ solution to your PCB requirements.

- Skilled workforce trained and continually assessed by our own on-site trainers.

- Offer troubleshooting teams of debug technicians/repairers who can go into a customer’s facility and work on their bonepile of PCB’s

The failed PCB generally goes into a debug area where the fault is diagnosed, repaired, and the PCB is re-tested If it passes, it ships; if it fails, it goes back around the debug loop. After three attempts the PCB is often classed as unreliable and scrapped.

As product life cycle becomes shorter, the debug techs are given less time to learn a new product, so often they wrongly diagnose the fault, leading to an increase of ‘end of line’ failures.

As part of the PCB service, if the IC’s are recovered using our IC recovery service that also includes electrical & mechanical test for further authenticity - these IC’s can then be :

- Used in a debug area to repair a failed assembly

- Used in a field return repair in the future

Varosa Engg offer a suite of tests - Visual Inspection, Key Functions, XRF, Solderability, 3D X-Ray Inspection, Memory Programming, Curve Trace, Decapsulation, Ionic Contamination, Extreme Temperature Test, Heated Solvent Test and more.

PREVIOUS PROJECTS HISTORY :

PCB OF CNC,PLC CONTROLLERS AND INDUSTRIAL, MEDICAL, MARINE PCB’S. INVERTER PCB’S, CPU PCB’S , POWER SUPPLY PCB’S AND MODULES (SMPS, UPS ), AC/DC SERVO DRIVES, VALVE CONTROLERS AND ACTUATORS (REXROTH, VICKERS), DISPLAYS, HMI, TEACH PENDANT, OPERATOR INTERFACES. ENCODERS AND LINEAR SCALES.

WE HAVE CARRIEDOUT SUCCESSFUL REPAIR ON THE FOLLOWING DRIVES AND VFDS AND CNC CONTROLLERS.

DISPLAYS AND HMI: MONI TOUCH, PROFACE, FANUC, SIEMENS, MAZAK ENCODERS AND LINEAR SCALE: HEIDENHAIN, ANILAM, ELECTRONICA, FAGOR, YASKAWA, SICK, TR. ROBOTICS: FANUC, ABB, KUKA.

SPECIAL MACHINERY AREA:

- HIGH FREQUENCY CONVERTERS USED IN IRON FOUNDRIES AND OFFSHORE JIGS off (INDUCTOTHERM)

- INDUCTION HARDNER ELECTRONICS ( EMA, GH,EFD)

- HIGH VOLTAGE POWER SUPPLY ,CATHODE RAY HEATING TRANSFORMERS ( LEYBOLD OPTICAL AR COATING MACHINE , NDRG 0850 )

- PRESSURE DIECASTING MACHINES UBEY,BHULER,WOLLEN SPRAY,TEACH PENDANT.

- INSTRUMENTATION AND MEDICAL ELECTRONICS.